Plus1 Story

Although there are many embedded Linux CPUs on the market, few were designed to address the needs of the IoT and industrial control markets directly.

Most CPUs found on popular boards such as the Raspberry Pi were initially meant for something else (for example, a set-top box) and were merely repurposed for the needs of the IoT and industrial control communities.

Such CPUs usually have adequate processing power but lack I/O features, which is not surprising: Set-top boxes have very different I/O needs than IoT or industrial control devices.

These CPUs are also rather complex, need multiple additional components to work, are available only in difficult-to-handle BGA packaging, and require six or eight-layer boards.

All this poses severe obstacles to low and medium-volume device vendors.

Take the BGA packaging as an example. Everything about BGA is an order of magnitude more complex compared to other packaging choices, such as LQFP.

BGA represents the cut-off line, where it becomes impossible to handle the chips manually. Everything from soldering to desoldering and verifying the assembly quality requires specialized and expensive equipment.

Smartphone manufacturers accept BGA challenges as the inevitable side effect of the desired board miniaturization that the technology enables,

but vendors of IoT or industrial control devices view this differently.

IoT and industrial control products rarely have any size pressure, and having to deal with ever-smaller IC packages only brings complications without any apparent benefits.

As another example, consider the logic levels of GPIO lines. As processor designs take advantage of ever-more advanced fabrication processes, chip supply voltages have also decreased.

Subsequently, standard semiconductor I/O libraries have dropped support for 5V and even 3.3V logic levels.

This did not bother the designers of set-top boxes and other "closed" products but was bad news for the architects of control hardware.

To summarize, there was an apparent gap between existing processor offerings and the requirements of IoT and industrial control applications.

Recognizing the unmet needs of IoT and industrial control vendors, Sunplus Technology Co., Ltd. and Tibbo Technology, Inc. in late 2017 set out to develop a Linux-grade chip that would directly address these markets.

The idea was to create a powerful SoC with I/O features and packaging specifically targeting IoT and industrial control applications, as well as the needs of low-to-medium-volume hardware manufacturers.

Thus, the Plus1 concept was born.

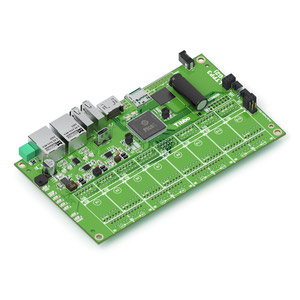

Here are the key characteristics of the SP7021, the first member of the new Plus1 line:

- Easy-to-use LQFP package

- Quad-core 1GHz Cortex-A7 CPU, plus A926 and 8051 cores

- Single 3.3V power*

- Integrated 128MB or 512MB DDR3 DRAM

- Eight 8-bit 5V-tolerant I/O ports, plus one high-current port

- Flexible Peripheral Multiplexing (PinMux)

- Dual PinMuxable Ethernet MACs

- Four PinMuxable Enhanced UARTs, plus one console UART

- Industrial operating temperature range: -40°C to 85°C

- Low EMI simplifies certification

- Linux distribution flexibility:

- Drivers mainlined into the official Linux kernel

- Ten-year supply guarantee

- And much more...

Read about Plus1 features

*Some limitations apply